English

English

DOI:

https://doi.org/10.36805/jtmmx.v6i1.10448Kata Kunci:

Refuse-Derived Fuel (RDF), Green Supply Chain Management (GSCM), Green Production, Integrative ReviewAbstrak

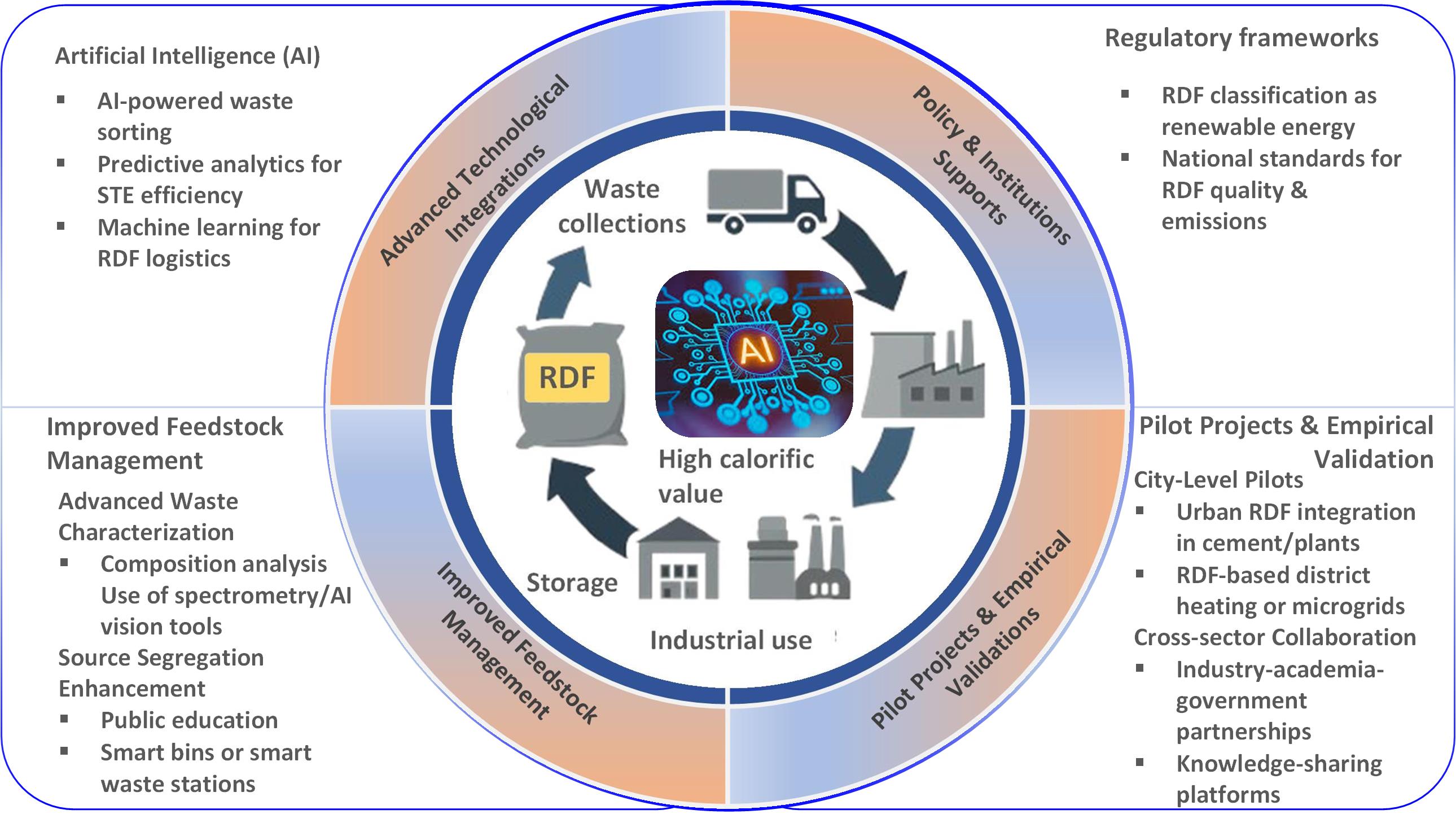

Pengelolaan limbah yang berkelanjutan dan sistem produksi ramah lingkungan menjadi fokus utama dalam

praktik rantai pasok modern. Refuse-Derived Fuel (RDF) sebagai bahan bakar alternatif yang berasal dari

limbah padat menunjukkan potensi besar dalam mendukung prinsip Green Supply Chain Management

(GSCM). Namun, integrasi RDF dalam kerangka GSCM masih belum banyak dibahas secara menyeluruh.

Penelitian ini bertujuan untuk mengkaji integrasi RDF dalam Sustainable Supply Chain Management

(GSCM) melalui metode tinjauan literatur integratif. Hasil kajian menunjukkan bahwa RDF tidak hanya

berkontribusi terhadap pengurangan volume limbah dan emisi, tetapi juga dapat meningkatkan efisiensi

energi dalam industri, terutama sektor manufaktur semen. Tantangan utama mencakup kualitas bahan baku

limbah, kompleksitas teknologi, serta kebijakan pendukung yang masih terbatas. Studi ini menawarkan

model konseptual yang memosisikan RDF sebagai penggerak strategis dalam produksi hijau. Dengan

pemahaman lintas bidang mengenai RDF, manajemen limbah, dan inovasi rantai pasok, RDF berpeluang

besar untuk diintegrasikan secara sistematis dalam strategi produksi berkelanjutan dan ekonomi sirkular.

Referensi

K. Sarquah et al., “Characterization of Municipal Solid Waste and Assessment of Its Potential for Refuse-Derived Fuel (RDF) Valorization,” Energies (Basel), vol. 16, no. 1, p. 200, 2022, doi: https://doi.org/10.3390/en16010200.

C. Vlachokostas, “Closing the Loop Between Energy Production and Waste Management: A Conceptual Approach Towards Sustainable Development,” Sustainability, vol. 12, no. 15, p. 5995, 2020, doi: https://doi.org/10.3390/su12155995.

S. Y. S. Rahayu, “Sustainable Development of Refuse-Derived Fuel (RDF) for Alternative Fuel Use in Cement Factories,” IOP Conf Ser Earth Environ Sci, vol. 1482, no. 1, p. 012056, 2025, doi: https://doi.org/10.1088/1755-1315/1482/1/012056.

M. Sarkar and Y. W. Seo, “Biodegradable Waste to Renewable Energy Conversion Under a Sustainable Energy Supply Chain Management,” Mathematical Biosciences and Engineering, vol. 20, no. 4, pp. 6993–7019, 2023, doi: https://doi.org/10.3934/mbe.2023302.

S. Suganal and G. K. Hudaya, “Bahan bakar co-firing dari batubara dan biomassa tertorefaksi dalam bentuk briket (Skala laboratorium),” Jurnal Teknologi Mineral dan Batubara, vol. 15, no. 1, pp. 31–48, 2019, doi: https://doi.org/10.30556/jtmb.Vol15.No1.2019.971.

B. H. M. Zahir, R. Nurcahyo, F. Farizal, and A. D. Wibowo, “Economic Assessment of Refuse-Derived Fuel (Rdf) Production as Waste Management Strategy and Alternative Fuel in Cement Kilns,” Journal of Law and Sustainable Development, vol. 12, no. 2, p. e3220, 2024, doi: https://doi.org/10.55908/sdgs.v12i2.3220.

Y. D. Prastika, M. Ulya, and M. F. F. Mu’tamar, “PENENTUAN PENERAPAN PRODUKSI BERSIH TERBAIK DI UKM KUE SERABI ‘APEN JULIT GETTAS’ KARANGANYAR-SUMENEP DAN ANALISIS NILAI TAMBAHNYA [Determination of the Best Application for Clean Production in the SME of Pancake ‘Apen Julit Gettas’ Karanganyar-Sumenep and Its Value Added Analysis],” Jurnal Teknologi & Industri Hasil Pertanian, vol. 24, no. 1, p. 31, Mar. 2019, doi: https://doi.org/10.23960/jtihp.v24i1.31-38.

M. Švažas, V. Navickas, E. Krajňáková, and J. Nakonieczny, “Sustainable Supply Chain of the Biomass Cluster as a Factor for Preservation and Enhancement of Forests,” Journal of International Studies, vol. 12, no. 2, pp. 309–321, 2019, doi: https://doi.org/10.14254/2071-8330.2019/12-2/20.

H. Kusumo and S. Rakasiwi, “Information System Supply Chain Management with FIFO Perpetual Method,” Advance Sustainable Science, Engineering and Technology, vol. 3, no. 2, May 2021, doi: https://doi.org/10.26877/asset.v3i2.9722.

A. D. Dwipayana and N. L. Darmayanti, “Green Energy Development Strategy Towards Green Logistics: Case Study At PT. Pelabuhan Indonesia III (Persero) Benoa Bali,” Jurnal Manajemen Industri dan Logistik, vol. 8, no. 1, pp. 81–96, Sep. 2024, doi: https://doi.org/10.30988/jmil.v8i1.1415.

C. Furqon, M. A. Sultan, H. W. Yuin, H. Hendrayati, and A. P. A, “Green Supply Chain Management Performance Measurement Using the Balanced Scorecard - Analytic Network Process in the Fresh Dairy Industry,” Jurnal Manajemen Industri dan Logistik, vol. 6, no. 2, pp. 297–308, May 2023, doi: https://doi.org/10.30988/jmil.v6i2.1308.

Jusuf Haurissa and Helen Riupassa, “ANALISA KONVEKSI PAKSA (PEMAKSAAN UDARA MASUK) PADA PROSES PEMBAKARAN BRIKET AMPAS SAGU”.

Jususf Haurissa, Helen Riupassa, Hendry Y. Nanlohy, and Suyatno, “PENGARUH PENAMBAHAN ADJUSTER PADA KOMPOR BRIKET TERHADAP JARAK PEMBAKARAN DAN LAJU PERPINDAHAN PANAS KONDUKSI”.

A. Z. Abidin et al., “Comparative Analysis of Waste Management Between Masaro and Refuse-Derived Fuel (RDF) Technologies in West Java,” E3s Web of Conferences, vol. 519, p. 04004, 2024, doi: https://doi.org/10.1051/e3sconf/202451904004.

A. Priyo Dwiarso, U. Marius Siahaan, and S. Maya Damayanti, “Project Identification And Selection to Prioritize the Best Alternative Project in the Context of Cement Manufacturing,” Journal of Engineering and Management in Industrial System, vol. 13, no. 1, pp. 1–13, 2025, doi: https://doi.org/10.21776/ub.jemis.2025.013.01.1.

Y. S. Kurniawan, H. O. Lintang, and L. Yuliati, “Preparation of green-emissive zinc oxide composites using natural betacyanin pigment isolated from red dragon fruit,” Indonesian Journal of Chemistry, vol. 21, no. 1, pp. 57–65, Feb. 2021, doi: https://doi.org/10.22146/ijc.52351.

N. Widha Setyanto, L. Riawati, R. Prasetyo Lukodono, and R. Ardianwiliandri, “PENENTUAN SETTING LEVEL OPTIMAL UNTUK PEMBUATAN BRIKET BERBAHAN BAKU LIMBAH DAUN PENYULINGAN NILAM,” 2016. [Online]. Available: http://Jemis.ub.ac.id

Siti Ajizah, Nur Hidayat, and Sri Surhatini, “Modelling Green Production Process in the Natural Dyes Batik Industry Using Cleaner Production Options”.

S. Peningkatan Produktivitas dan Kualitas Kedelai Lokal, N. Siswi Indastri, I. Yuliasih, G. Pramuhadi, B. Pengkajian Teknologi Pertanian Banten Jl Ciptayasa Km, and C. Serang, “STRATEGIES FOR INCREASING LOCAL SOYBEAN PRODUCTIVITY AND QUALITY WITH A GREEN PRODUCTIVITY APPROACH,” Jurnal Teknologi Industri Pertanian, vol. 28, no. 3, pp. 342–353, doi: https://doi.org/10.24961/j.tek.ind.pert.2018.28.3.342.

N. Siswi Indrasti, M. Romli, I. Sailah, and A. Permatasari, “CO-COMPOSTING OF BELTPRESS SOLID WASTE AND RICE STRAW BY USING AERATED STATIC PILE.”

M. Dahlan, E. Sulfiana, S. Purna yudha, and Muh. N. H. Amaluddin, “STUDI KARAKTERISTIK BRIKET ARANG BIOMASSA BERBASIS SCREW PRESS,” Jurnal Rekayasa Mesin, vol. 15, no. 3, pp. 1643–1653, Dec. 2024, doi: https://doi.org/10.21776/jrm.v15i3.1824.

Rianto Wibowo, “ANALISIS THERMAL NILAI KALOR BRIKET AMPAS BATANG TEBU DAN SERBUK GERGAJI.”

I. Urwatul Wusko, A. Noraidi Maulana, A. Sabitah, and Misbachudin, “UJI KUALITAS BRIKET ARANG DARI SEKAM PADI DAN SERBUK KAYU SEBAGAI BAHAN BAKAR ALTERNATIF,” Jurnal Rekayasa Mesin, vol. 15, no. 3, pp. 1425–1436, Dec. 2024, doi: https://doi.org/10.21776/jrm.v15i3.1694.

N. O. Solomon, P. Simpa, O. A. Adenekan, and S. C. Obasi, “Sustainable Nanomaterials’ Role in Green Supply Chains and Environmental Sustainability,” Engineering Science & Technology Journal, vol. 5, no. 5, pp. 1678–1694, 2024, doi: https://doi.org/10.51594/estj.v5i5.1136.

Peni Shoffiyati and Fesa Putra Kristianto, “FURNITURE INDUSTRY GREEN SUPPLY CHAIN SUCCESS FACTORS: A SYSTEMATIC LITERATURE REVIEW,” Jurnal Teknologi Industri Pertanian, vol. 35, no. 1, pp. 95–106, Apr. 2025, doi: https://doi.org/10.24961/j.tek.ind.pert.2025.35.1.95.

A. Muhammad, B. M. Naidu, V. P. K. Sundram, M. Z. S. M. Hussain, L. L. Chew, and F. A. Amirrudin, “Sustainable Waste Management in Malaysia: Leveraging Supply Chain Solutions for a Greener Future,” Information Management and Business Review, vol. 15, no. 3(SI), pp. 147–154, 2023, doi: https://doi.org/10.22610/imbr.v15i3(si).3469.

S. Yahya, B. Susanti, and H. Fitriani, “Financial Feasibility Analysis Of Urban Waste Processing As Refused Derived Fuel For Cement Company,” Eduvest - Journal of Universal Studies, vol. 4, no. 6, pp. 5352–5366, Jun. 2024, doi: https://doi.org/10.59188/eduvest.v4i6.1424.

D. Prihandoko, C. W. Purnomo, P. K. Widyaputra, and N. Nasirudin, “Application of Refuse-Derived Fuel (RDF) Plant in Piyungan Landfill Municipal Solid Waste Management,” ASEAN Journal of Chemical Engineering, vol. 22, no. 2, p. 296, Dec. 2022, doi: https://doi.org/10.22146/ajche.75560.

F. D. Robi, S. Bambang, and M. B. Toriki, “Techno-Economic Study of the Use of Refuse-Derived Fuel (RDF) Biomass Waste Conversion into Electricity Using the Three-Stage Gasification Method and Dual Fuel Diesel Engine on Batam Island,” in Journal of Physics: Conference Series, Institute of Physics, 2025. doi: https://doi.org/10.1088/1742-6596/2942/1/012023.

Robi Fajerin Darmawan and Bambang Sudarmanta, “Kajian Tekno Ekonomi Terkait Konversi Limbah Biomassa Refuse Derived Fuel (RDF) Menjadi Listrik Melalui Metode Gasifikasi Tiga Tingkat dan Mesin Diesel Dual Fuel di Pulau Batam,” EduInovasi: Journal of Basic Educational Studies, vol. 4, no. 2, pp. 1331–1361, Jul. 2024, doi: https://doi.org/10.47467/edu.v4i2.4319.

P. Krawczyk, K. Badyda, and A. Mikołajczak, “The environmental impact of refuse derived fuel co-combustion with lignite,” MATEC Web of Conferences, vol. 240, p. 05013, Nov. 2018, doi: https://doi.org/10.1051/matecconf/201824005013.

M. Azam, S. S. Jahromy, W. Raza, C. Jordan, M. Harasek, and F. Winter, “Comparison of the combustion characteristics and kinetic study of coal, municipal solid waste, and refuse‐derived fuel: Model‐fitting methods,” Energy Sci Eng, vol. 7, no. 6, pp. 2646–2657, Dec. 2019, doi: https://doi.org/10.1002/ese3.450.

G. A. Kristanto and E. Rachmansyah, “The application of Refuse Derived Fuel (FDR) from commercial solid wastes to reduce CO 2 emissions in the cement industry: a preliminary study,” IOP Conf Ser Earth Environ Sci, vol. 423, no. 1, p. 012014, Jan. 2020, doi: https://doi.org/10.1088/1755-1315/423/1/012014.

I. M. W. Wijaya, I. G. N. M. Wiratama, I. K. A. Putra, and N. P. C. D. Atmaja, “Unlocking the Energy Potential of Temple Waste and Coconut Fiber through Refuse Derived Fuel Production toward Sustainable Energy,” Ecological Engineering & Environmental Technology, vol. 24, no. 7, pp. 19–29, Jul. 2023, doi: https://doi.org/10.12912/27197050/169362.

M. M. Mateus, D. Cecílio, M. C. Fernandes, and M. J. Neiva Correia, “Refuse derived fuels as an immediate strategy for the energy transition, circular economy, and sustainability,” Bus Strategy Environ, vol. 32, no. 6, pp. 3915–3926, Sep. 2023, doi: https://doi.org/10.1002/bse.3345.

A. Janda and W. M. Urbańska, “CURRENT PROBLEMS IN THE COMBUSTIBLE MUNICIPAL WASTE MANAGEMENT – A CASE STUDY FOR PRE-RDF, RDF AND SRF MANAGEMENT IN POLAND,” Zeszyty Naukowe SGSP, vol. 2, no. 89, pp. 75–92, May 2024, doi: https://doi.org/10.5604/01.3001.0054.5447.

M. Budihardjo, E. Yohana, B. Ramadan, A. Puspita, S. Adhana, and J. Rizkiana, “Study of Potential Refuse Derived Fuels as Renewable Alternative Energy from a Jatibarang Landfill,” Pol J Environ Stud, vol. 31, no. 4, pp. 3013–3020, Jun. 2022, doi: https://doi.org/10.15244/pjoes/145614.

T. Li, W. Li, Z. Lou, and L. Wang, “Comprehensive Analysis of Industrial Solid-Waste-to-Energy by Refuse-Derived Fuel Technology: A Case Study in Shanghai,” Sustainability, vol. 16, no. 10, p. 4234, May 2024, doi: https://doi.org/10.3390/su16104234.

J. C. I. Rabetanetiarimanana, M. H. Radanielina, H. T. Rakotondramiarana, and D. Morau, “A Survey of the Gasification of Residual Household Waste,” Smart Grid and Renewable Energy, vol. 13, no. 11, pp. 268–293, 2022, doi: https://doi.org/10.4236/sgre.2022.1311017.

T. Weerasak and S. Sanongraj, “Potential of Producing Refuse Derived Fuel (RDF) from Municipal Solid Waste at Rajamangala University of Technology Isan Surin Campus,” Applied Environmental Research, pp. 85–91, Jun. 2015, doi: https://doi.org/10.35762/AER.2015.37.2.7.

D.-W. Shun, D.-H. Bae, S.-H. Jo, and S.-Y. Lee, “Combustion Study of 1MWe Circulating Fluidized Boiler for RDF,” Korean Chemical Engineering Research, vol. 50, no. 5, pp. 837–842, Oct. 2012, doi: https://doi.org/10.9713/kcer.2012.50.5.837.

N. Chommontha, A. Phongphiphat, K. Wangyao, S. Patumsawad, and S. Towprayoon, “Effects of operating parameters on co-gasification of coconut petioles and refuse-derived fuel,” Waste Management & Research: The Journal for a Sustainable Circular Economy, vol. 40, no. 5, pp. 575–585, May 2022, doi: https://doi.org/10.1177/0734242X211003974.

P. C. Mandala, I. D. A. A. Warmadewanthi, and R. Aniza, “STUDY OF OPTIMALIZATION SOLID WASTE OF REFUSE DERIVES FUEL (RDF) AT LANDFILL GRIYO MULYO, SIDOARJO DISTRICT,” INDONESIAN JOURNAL OF URBAN AND ENVIRONMENTAL TECHNOLOGY, pp. 30–41, Feb. 2024, doi: https://doi.org/10.25105/urbanenvirotech.v7i1.19315.

W. Zamrudy, S. Santosa, A. Budiono, and E. Naryono, “A review of Drying Technologies for Refuse Derived Fuel (RDF) and Possible Implementation for Cement Industry,” Int J Chemtech Res, vol. 12, no. 01, pp. 307–315, 2019, doi: https://doi.org/10.20902/IJCTR.2019.120137.

I. A. S. Wulandari, H. C. Wahyuni, I. Mardiyah, and N. R. Hanun, “Environment Performance Index Assessment on Food Production: A Case Study in Indonesia,” Jurnal Teknik Industri, vol. 23, no. 2, pp. 93–104, Aug. 2022, doi: https://doi.org/10.22219/jtiumm.vol23.no2.93-104.

D. K. Hadi, A. P. Setiawan, O. V. Indrian, and E. F. Rosyid, “Evaluation of Sustainability Supply Chain Performance in the Food Industry: A Case Study,” Jurnal Teknik Industri, vol. 24, no. 2, pp. 95–108, Aug. 2023, doi: https://doi.org/10.22219/jtiumm.vol24.no2.95-108.

I. A. S. Wulandari, N. R. Hanun, and A. S. Cahyana, “A Model for Enhancing the Environmental Performance by Integrating Lean and Green Productivity Concept: A Case Study of Food Production,” Jurnal Teknik Industri, vol. 25, no. 1, pp. 83–96, Feb. 2024, doi: https://doi.org/10.22219/JTIUMM.Vol25.No1.83-96.

A. Setiawan Rusdianto, M. Choiron, and N. Novijanto, “KARAKTERISASI LIMBAH INDUSTRI TAPESEBAGAI BAHAN BAKU PEMBUATAN BIOPELLET CHARACTERIZATION OF TAPE INDUSTRY WASTE AS BIO PELLET RAW MATERIAL.”

A. S. Rusdianto, F. Septyatha, and M. Choiron, “Analisis Kelayakan Finansial Industri Bio-pellet Kulit Kopi di Kabupaten Jember Financial Feasibility Analysis of Coffee Peel Bio-pellet Industry in Jember Regency,” Jurnal Teknologi dan Manajemen Agroindustri, vol. 7, pp. 89–94, 2018, doi: https://doi.org/10.21776/ub.industria.2018.007.02.3.

Yusriana, Rachman Jaya, and Meilita T. Sembiring, “EKONOMI SIRKULAR PADA MANAJEMEN RANTAI PASOK AGROINDUSTRI: KONSEPTUAL DAN RANCANGAN IMPLEMENTASI,” Jurnal Teknologi Industri Pertanian, pp. 196–205, Aug. 2023, doi: https://doi.org/10.24961/j.tek.ind.pert.2023.33.2.196.

Efri Yulistika, Suprihatin, and Purwoko, “POTENSI PENERAPAN KONSEP EKONOMI SIRKULAR UNTUK PENGEMBANGAN INDUSTRI TAHU YANG BERKELANJUTAN,” Jurnal Teknologi Industri Pertanian, pp. 254–266, Dec. 2023, doi: https://doi.org/10.24961/j.tek.ind.pert.2023.33.3.254.

D. B. Olawade et al., “Smart waste management: A paradigm shift enabled by artificial intelligence,” Waste Management Bulletin, vol. 2, no. 2, pp. 244–263, Jun. 2024, doi: https://doi.org/10.1016/j.wmb.2024.05.001.

V. Melinda, T. Williams, J. Anderson, J. G. Davies, and C. Davis, “Enhancing Waste-to-Energy Conversion Efficiency and Sustainability Through Advanced Artificial Intelligence Integration,” International Transactions on Education Technology (ITEE), vol. 2, no. 2, pp. 183–192, May 2024, doi: https://doi.org/10.33050/itee.v2i2.597.

Unduhan

Diterbitkan

Terbitan

Bagian

Lisensi

Hak Cipta (c) 2025 Jurnal Teknik Mesin Mechanical Xplore

Artikel ini berlisensi Creative Commons Attribution 4.0 International License.