Fabrication and Structural Integrity Analysis of a Jenang Mixer Machine: A Solution for Modernizing Traditional Indonesian Food Production

DOI:

https://doi.org/10.36805/jtmmx.v6i1.10414Kata Kunci:

Jenang mixer machine, 3D Design, Structural analysis, Safety factorAbstrak

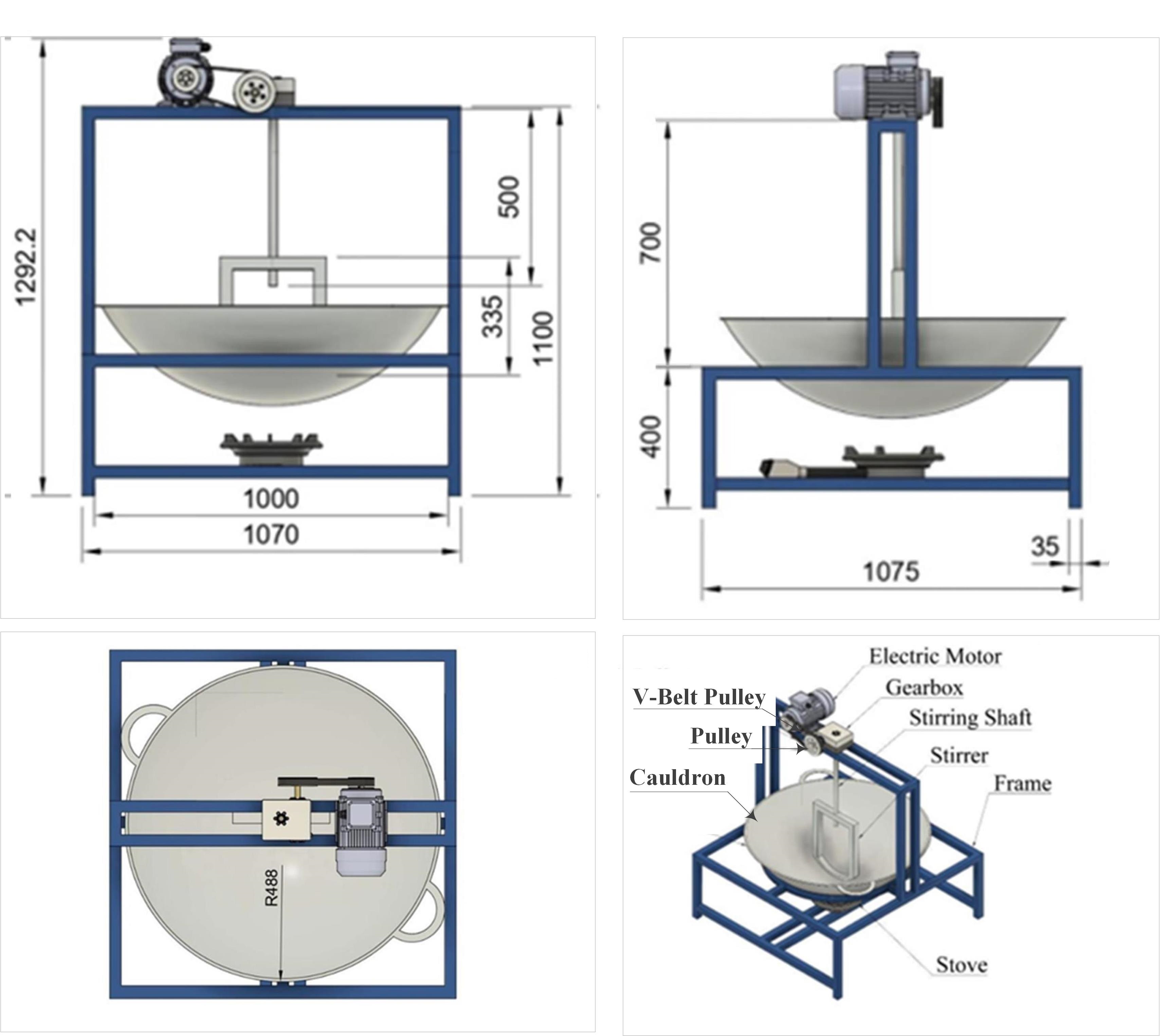

The design and fabrication of the Jenang mixer machine are carried out to enhance the efficiency of household industrial-scale Jenang production. The machine is designed using an engineering approach based on numerical analysis and the Design for Manufacture and Assembly (DFMA) method. The drive power calculation shows a minimum requirement of 2072.7 Watts; therefore, a 3 HP electric motor equipped with a gearbox is used to produce significant torque at low revs. Analysis of the frame strength using static simulations in Fusion 360 software revealed that the machine structure had a safety factor of 15 and a maximum displacement of only 0.006 mm, indicating a robust and stable structure. The fabrication results indicate that the machine comprises 12 principal components and operates reliably in evenly stirring the Jenang dough, making it suitable for small to medium-scale production.

Referensi

A. Wibowo, “Jenang: Food production system based on myths in Java, Indonesia,” IOP Conf. Ser. Earth Environ. Sci., vol. 828, no. 1, (2021). doi: https://doi.org/10.1088/1755-1315/828/1/012056.

A. Adiatma, “Community Empowerment Through the Jenang Tebokan Kirab Tradition in Kaliputu Village , Kota District , Kudus District in Improving the Community ’ s Economy,” vol. 2, pp. 57–62, (2023). Doi: https://doi.org/10.53797/anp.jssh.v4i2.8.2023.

S. A. Raida, I. Y. Wardhani, and A. D. Kharisa, “Analysis of Ethnostem Content in Making Jenang Kudus A Science Learning Resource for Junior High School Students,” vol. 2, no. 1, pp. 32–47, 2025.

R. Sonia and R. Purwaningsih, “Desain Peningkatan Eco-Efficiency Produk Jenang Pada UMKM Jenang Kudus Rizqina dengan Menggunakan Pendekatan Life Cycle Assessment ( LCA ),” Ind. Eng. Online J., vol. 13, no. 1, p. 1-12, 2024. [Online].

Y. Kurniati Werdiningsih, . S., . A., and W. Tia Rinnjani, “Revitalization of Traditional Food in Central Java,” KSS, vol. 7, no. 14, pp. 504–510, (2022). doi: https://doi.org/10.18502/kss.v7i14.12002.

K. Elsty and W. N. Sari, “Traditional Cake and Beverage Museum Planning : The Documentation of Potential Traditional Cake and Beverage as Indonesian Gastronomy to Preserve and Promote Indonesian Culture,” vol. 2024, no. Incogite. Atlantis Press International BV, (2024). doi: https://doi.org/10.2991/978-94-6463-585-0.

C. R. Lucius, Caroline, T. Imanto, and D. Roespinoedji, “Identification of Old Javanese Food in Serat Chentini Through Visual Storytelling,” Rev. Int. Geogr. Educ. Online, vol. 11, no. 6, pp. 1332–1339, (2021). doi: https://doi.org/10.48047/rigeo.11.06.147.

V. K. Putri, T. S. Pitana, and W. Setyaningsih, “The resilience of Jenang industrial traditional houses against development of the times,” IOP Conf. Ser. Earth Environ. Sci., vol. 778, no. 1, (2021). doi: https://doi.org/10.1088/1755-1315/778/1/012028.

S. A. Sari, J. Hutabarat, H. Setyawati, and A. Artiyani, “STRATEGI PENINGKATAN PRODUKSI JENANG KETAN DENGAN PENERAPAN MESIN PENGADUK DI HOME INDUSTRY KECAMATAN WAGIR KABUPATEN MALANG,” Ind. Inov. J. Tek. Ind., vol. 15, no. 1, pp. 186–190, (2025). doi: https://doi.org/10.36040/industri.v15i1.9066.

; Supriyanto Supriyanto, I. M. Muslimin, and F. Rhohman, “Perancangan Alat Pengaduk Jenang Ketan Berkapasitas 20 Kg,” J. Invotek, vol. 7, pp. 750–758, 2023.

Z. Abidin and F. Rhohman, “Rancang Bangun Rangka Pada Alat Pengaduk Jenang Ketan Berkapasitas 20 Kg,” J. Mesin Nusanatara, vol. 7, pp. 1233–1240, 2023.

A. Shkut, “a Methodological Approach To Assessing the Durability of Welded Structures of Screens Using Solidworks Simulation Software,” Nauk. Visnyk Natsionalnoho Hirnychoho Universytetu, no. 6, pp. 79–85, (2023). doi: https://doi.org/10.33271/nvngu/2023-6/079.

N. Dagar, R. Sharma, M. Lal Rinawa, S. Gupta, V. Chaudhary, and P. Gupta, “Design and analysis of piston using aluminum alloy and composites in Solidworks and Ansys,” Mater. Today Proc., vol. 67, pp. 784–791, 2022, doi: https://doi.org/10.1016/j.matpr.2022.07.318.

S. Setiawati, W. Aini, and L. Pridayati, “Community Empowerment Based on Local Materials,” Kolok. J. Pendidik. Luar Sekol., vol. 12, no. 2, pp. 443–449, Oct. (2024). doi: https://doi.org/10.24036/kolokium.v12i2.922.

N. T. Fernanda, K. Kusnandar, and R. K. Adi, “Strategi Pengembangan Usaha Mikro Kecil dan Menengah (UMKM) Agroindustri Jenang Kedunggudel di Desa Kenep Kabupaten Sukoharjo”, JIA (J. Ilm. Agribisnis), vol. 9, no. 5, pp. 422–435, (2024). http://doi.org/10.37149/JIA.v9i5.1482.

F. Firdausiyah, J. Juhadi, and A. Pujiati, “Inheritance of Gusjigang Value in the Young Generation in Environment of Jenang Msme Kaliputu Village,” JESS, vol. 10, no. 2, pp. 58-66, (2021). doi: . https://doi.org/10.15294/jess.v10i2.52185.

D. L. Fithri, B. Gunawan, H. Risnawati, R. Rahmawati, and S. Mulyani, “Pemberdayaan UKM Jenang Kudus Melalui Optimalisasi Kapasitas Produksi dan Pendampingan Manajemen Usaha,” vol. 15, no. 3, pp. 492–498, 2024.

A. M. Devano, Y. Tarigan, M. A. Priyono, M. N. Daffa'ulhaq, “Analysis of Supply Chain Management Performance Measurement: A Case Study in an Indonesian Manufacturing Company,” no. August, pp. 1–11, (2023). Doi: http://dx.doi.org/10.4108/eai.7-11-2023.2342435.

A. A. Akhmetgareeva, R. R. Parfilova, and I. M. Safarov, “ECONOMIC EFFICIENCY OF AUTOMATION OF PRODUCTION PROCESSES IN SMALL AND MEDIUM BUSINESSES,” Ekon. I Upr. Probl. RESHENIYA, vol. 11/9, no. 152, pp. 91–97, (2024). doi: https://doi.org/10.36871/ek.up.p.r.2024.11.09.013.

A. B. N. R. Putra et al., “Hilirisasi TTG Mesin Pengaduk Jenang Bersensor Speed Control Sebagai Pemercepat Income dan Pemberdayaan Makanan Daerah Desa Duren,” Pros. Hapemas, vol. 4, no. 1, pp. 45–51, 2024.

H. Winkler, F. Franke, S. Franke, and R. Riedel, “Optimization of Production Processes in MSMEs: Practical Methodology for the Acquisition of Process Information,” in in Advances in Production Management Systems. Smart Manufacturing and Logistics Systems: Turning Ideas into Action, Cham, pp. 51-59. (2022) doi: https://doi.org/10.1007/978-3-031-16407-1_7.

V. E. Faizah, “Pengembangam UMKM Jenang Godog melalui Pendampingan Pembaruan Kemasan Produk dan Digital Marketing,” vol. 02, no. 02, pp. 99–113, 2024.

S. D. Prasetyo et al., “Optimization of Photovoltaic Thermal Collectors Using Fins: A Review of Strategies for Enhanced Solar Energy Harvesting,” Math. Model. Eng. Probl., vol. 10, no. 4, pp. 1235–1248, Aug. (2023). doi: https://doi.org/10.18280/mmep.100416.

Z. Arifin, D. D. D. P. Tjahjana, R. A. Rachmanto, S. Suyitno, S. D. Prasetyo, and T. Trismawati, “Redesign Mata Bor Tanah Untuk Pembuatan Lubang Biopori Di Desa Puron, Kecamatan Bulu, Kabupaten Sukoharjo,” Mek. Maj. Ilm. Mek., vol. 19, no. 2, p. 60, (2020). doi: https://doi.org/10.20961/mekanika.v19i2.43393.

S. D. Prasetyo, F. J. Regannanta, A. R. Birawa, and M. S. Alfaridzi, “Techno-Economic Evaluation of Hybrid Photovoltaic-Wind Energy Systems for Indonesian Government Buildings,” J. Sustain. Energy, vol. 2, no. 3, pp. 132–144, (2023). doi: https://doi.org/10.56578/jse020303.

D. Sugiyanto, A. Darius, H. Susanto, A. S. Uyun, J. Mai, and M. Syahrullah, “Perancangan Mesin Pengaduk Dodol dengan Kapasitas 40 Kg untuk Meningkatkan Produksi Pengolahan Dodol Betawi,” J. Kaji. Tek. Mesin, vol. 7, no. 1, pp. 1–6, (2022). https://doi.org/10.52447/jktm.v7i1.5939.

A. D. Setiawan, T. N. Zahari, F. J. Purba, A. O. Moeis, and A. Hidayatno, “Investigating policies on increasing the adoption of electric vehicles in Indonesia,” J. Clean. Prod., vol. 380, p. 135097, Dec. (2022). doi: https://doi.org/10.1016/j.jclepro.2022.135097.

C. Retnaningsih, B. Irmawati, B. B. Retnawati, and O. Ruenda, “Development and innovation of locally inspired food products by Micro, Small, and Medium Enterprises (MSMEs) in Central Java, Indonesia,” IOP Conf. Ser. Earth Environ. Sci., vol. 1338, no. 1, (2024). doi: https://doi.org/10.1088/1755-1315/1338/1/012066.

S. D. Prasetyo, C. Harsito, Sutanto, and Suyitno, “Energy consumption of spray dryer machine for producing red natural powder dye and its stability,” in AIP Conf. Proc. 2097, 030076, (2019). doi: 1 https://doi.org/10.1063/1.5098251.

E. Menacho-Mendoza, R. Cedamanos-Cuenca, and A. Díaz-Suyo, “Stress analysis and factor of safety in three dental implant systems by finite element analysis,” Saudi Dent. J., vol. 34, no. 7, pp. 579–584, (2022). doi: https://doi.org/10.1016/j.sdentj.2022.08.006.

Aji Abdillah Kharisma and Muhammad Erlian Marsaoly, “Analisis Kegagalan pada Rangka Mesin Perontok Padi Kapasitas 1 Ton/Jam Menggunakan Metode Von Misses,” J. Rekayasa Mesin, vol. 20, no. 2, pp. 13–18, (2021). doi: https://doi.org/10.36706/jrm.v20i2.64.

C. L. C. Roxas et al., “Design for Manufacturing and Assembly ( DfMA ) and Design Challenges , Trends and Developments,” Buildings, vol. 13, no. 5, p. 1164, (2023). https://doi.org/10.3390/buildings13051164.

S. Montazeri, Z. Lei, and N. Odo, “Design for Manufacturing and Assembly (DfMA) in Construction: A Holistic Review of Current Trends and Future Directions,” Buildings, vol. 14, no. 1,p. 1-20, (2024). doi: https://doi.org/10.3390/buildings14010285.

M. I. A. Razak, M. A. Khoiry, W. H. W. Badaruzzaman, and A. H. Hussain, “DfMA for a Better Industrialised Building System,” Buildings, vol. 12, no. 6, (2022). doi: https://doi.org/10.3390/buildings12060794.

R. You and S. Pu, “Distributed Learning over Arbitrary Topology: Linear Speed-Up with Polynomial Transient Time,” arXiv, vol 1, p. 1-43, 2025, https://doi.org/10.48550/arXiv.2503.16123.

D. Wei, L. Chen, J. Wang, and X. Yao, “Design of Automatic Control System for Constant Tension and Linear Speed of Rewinder Machine,” Engineering Letters, vol. 29, no. 1, (2021).

S. D. Prasetyo, Y. Trisnoaji, Z. Arifin, and A. A. Mahadi, “Harnessing unconventional resources for large-scale green hydrogen production: An economic and technological analysis in Indonesia,” Unconv. Resour., vol. 6, no. December 2024, p. 100174, (2025). doi: https://doi.org/10.1016/j.uncres.2025.100174.

J Jingyeong Im, Taeho Kwon, Seungho Lee, Donghan Kim, Hyungtae Cho, Wangyun Won, and Boram Gu, “Unveiling the impact of internal structure on boil-off gas generation in moving liquid hydrogen (LH2) transport trailer,” Renew. Sustain. Energy Rev., vol. 216, no. October 2024, p. 115634, (2025). doi: https://doi.org/10.1016/j.rser.2025.115634.

B. Jourdain and S. Menozzi, “Convergence Rate of the Euler-Maruyama Scheme Applied to Diffusion Processes with L Q -- L $rho$ Drift Coefficient and Additive Noise,” pp. 1–30, 2021, [Online]. Available: http://arxiv.org/abs/2105.04860

K. Kudelina, T. Vaimann, B. Asad, A. Rassõlkin, A. Kallaste, and G. Demidova, "Trends and Challenges in Intelligent Condition Monitoring of Electrical Machines Using Machine Learning," Applied Sciences, vol. 11, no. 6., (2021). doi: https://doi.org/10.3390/app11062761.

H. Tiismus, A. Kallaste, T. Vaimann, and A. Rass, “State of the art of additively manufactured electromagnetic materials for topology optimized electrical machines,” vol. 55, no. November 2021, (2022). doi: https://doi.org/10.1016/j.addma.2022.102778.

Y. Shi, D. Wang, H. Qin, X. Chen, J. Han, and Z. Zhang, “Strength reduction factor spectra for SDOF systems with structural fuses,” Soil Dyn. Earthq. Eng., vol. 169, p. 107895, (2023). doi: https://doi.org/10.1016/j.soildyn.2023.107895.

M. Muscat, P. Mollicone, N. Mantel, and J. H. You, “Insight into the structural integrity assessment of the European DEMO Fusion Reactor Divertor ( Part I : General discussion ),” Fusion Eng. Des., vol. 214, no. October 2024, p. 114928, (2025). doi: https://doi.org/10.1016/j.fusengdes.2025.114928.

Unduhan

Diterbitkan

Terbitan

Bagian

Lisensi

Hak Cipta (c) 2025 Jurnal Teknik Mesin Mechanical Xplore

Artikel ini berlisensi Creative Commons Attribution 4.0 International License.